Peering at a Paint Film Cross-section

I was asked to investigate surface defects on painted timber MDF boards. A combination of metallography and microscopy techniques helped me see through to the core of the issue.

A Problem with Pipes - Leaks & Corrosion

For this Case Study, I examine a section of steel pipework which was used within a steam boiler system, and had developed a leak.

The Collapsing Chair - A Case of Workplace Injury

An office worker sustained personal injuries when her office chair collapsed as she attempted to sit down, injuring her wrist in the process. I was instructed to examine the chair, and determine the cause of failure.

The Chlorinated Shorts - A Case of Personal Injury.

For this case, I was asked to examine and analyse an article of clothing worn by a swimmer, which may be exposed to a high concentration of swimming pool cleaning products.

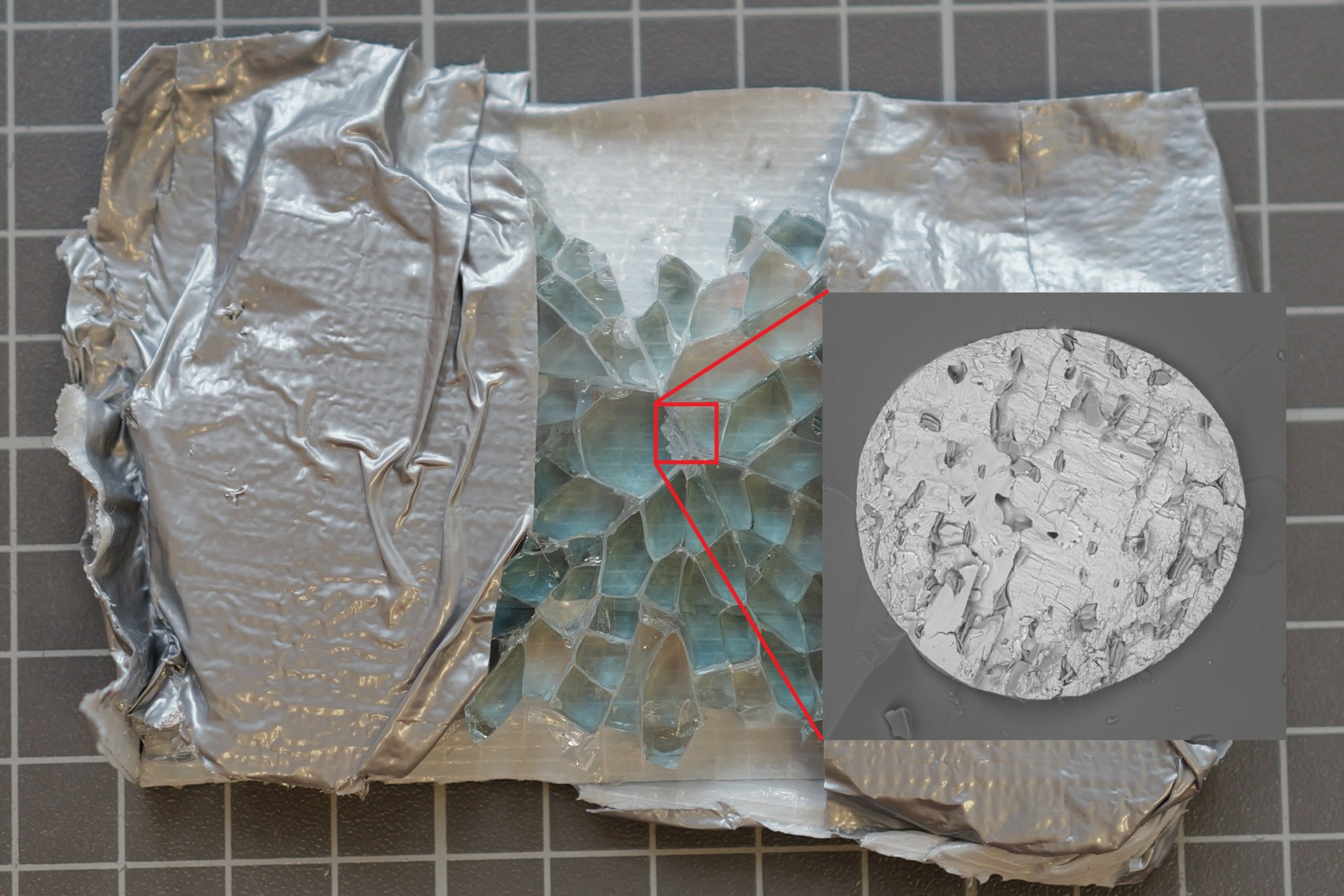

Nickel Sulphide Inclusions in Glass

In a recent case, I was contacted by a facade inspection specialist, who had suspected a nickel sulphide inclusion had fractured an expensive window pane. Finding a nickel sulphide can be a little bit like finding a needle in a haystack, and requires careful examination and specialist equipment.

Crack Examination in Electronic Components

I was contacted by an Irish-based multinational corporation, who produce bespoke electronic goods for specific communication applications. One particular critical component was found to be having intermittent failures on a specific LED bulb. What was initially invisible to the naked eye quickly became apparent. There was a small crack in the copper track running through the circuit board.

Steel Bolts - Cutting, Grinding, Polishing

I am regularly asked to examine the micro structure of steel components, such as nuts, bolts, plates, etc. Often, this is just for quality control purposes, or to evaluate changes in production processes. Occasionally, litigation is involved.

Measuring and Reducing Corrosivity

I was hired by this client to evaluate the corrosivity of their product against steel and aluminium, in accordance with given test methods. Matchbox sized coupons of steel and aluminium were prepared by cleaning them mechanically and chemically, before they were immersed in the flame retardant liquid for 30 days.

Faulty Plywood: Failure Analysis & Quality Testing

One of the first cases I was ever involved with was regarding high-quality timber doors that had been installed in a premier shopping mall. Shortly after installation, the paint on the doors began to peel, and the joinery who had performed the installation was forced to replace the doors at their own cost.